Get Involved: Click on these Mission Resources

Live Stream

The Epiphyte repo includes version BOMs and other project docs; issues, milestones and a forum.

OpenAir’s server hosts an active Epiphyte channel for sharing and general discussion

Every Monday at 12pm EST, we hold a 1-hour live stream on Streamyard / Youtube Live. All are welcome to tune in.

Summary & Mission Objectives

Epiphyte is a desk-scale, open source direct air capture (DAC)* prototype designed by volunteer members of the OpenAir Collective.

* Direct Air Capture (DAC) is a technology that removes carbon dioxide (CO2) directly from the atmosphere using specialized chemical and physical methods, aiming to mitigate climate change by reducing greenhouse gas emissions.

To continuously and rapidly evolve the Epiphyte design through a global peer-production* network, with contributions from a growing number of individuals and teams all over the world.

Epiphyte will be an open source global platform for DAC R&D, practical applications, and creative experimentation.

* Peer production describes systems of collaborative research, problem-solving and product development that rely upon the voluntary contributions of distributed independent actors participating in an open network.

‘Hello World’: Epiphyte Build #1

Fall - Winter 2023

University of Pennsylvania (Philadelphia, PA)

10 Minute Epiphyte Tour

Webinar: Summary of Build #1 Results and New Problems to solve. (Dec 2023)

Build #1 Background

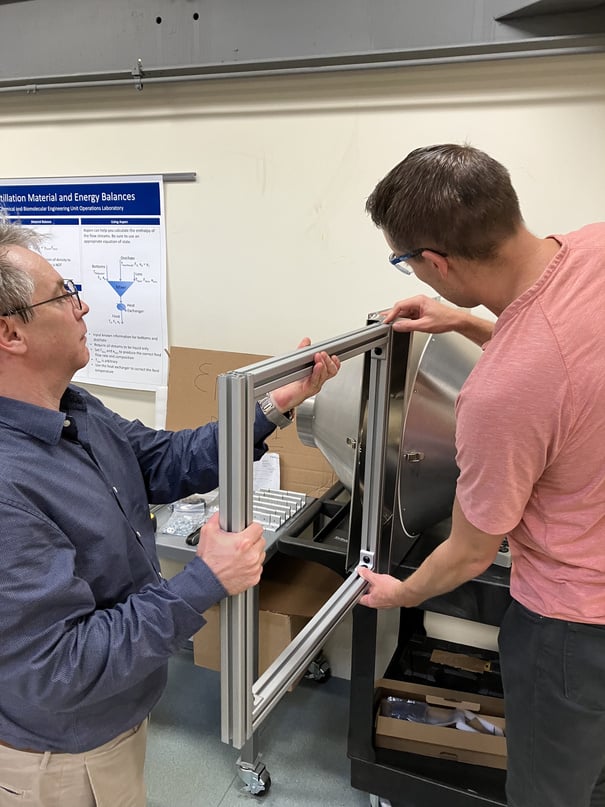

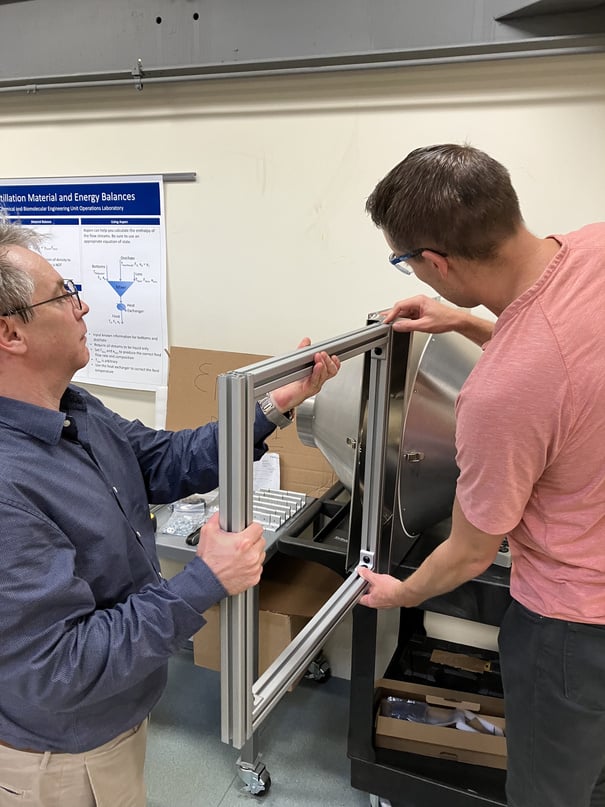

In fall of 2023, the first “Hello World” Epiphyte prototype was built by OpenAir volunteers David Wilson, Chuck Pierson, Ling Kong and Seth Sternberg, following a several month long collaborative design process carried out on weekly zooms, and over OpenAir’s Discord server.

The design was heavily inspired by an early working prototype developed by Octavia Carbon, based in Nairobi, Kenya.

The build was hosted at the University of Pennsylvania’s Department of Chemical and Biomolecular Engineering in Philadelphia.The goal of this first build was to complete a basic functional ‘kernel’ device that 1. achieved a verifiable level of CO2 removal, and 2. could provide a starting point for all future experimentation and improvements carried out by a global community, anchored by university teams located all over the world.

‘Hello World’ Prototype components

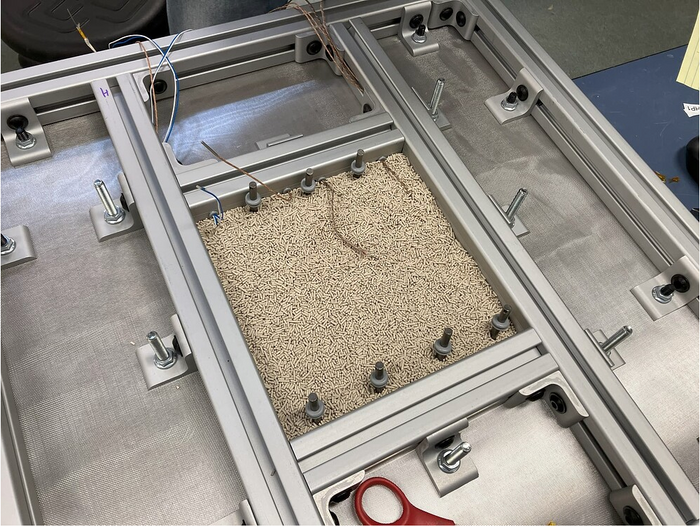

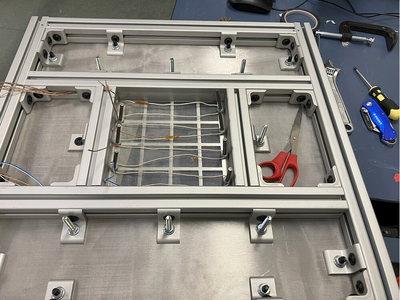

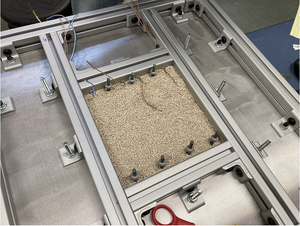

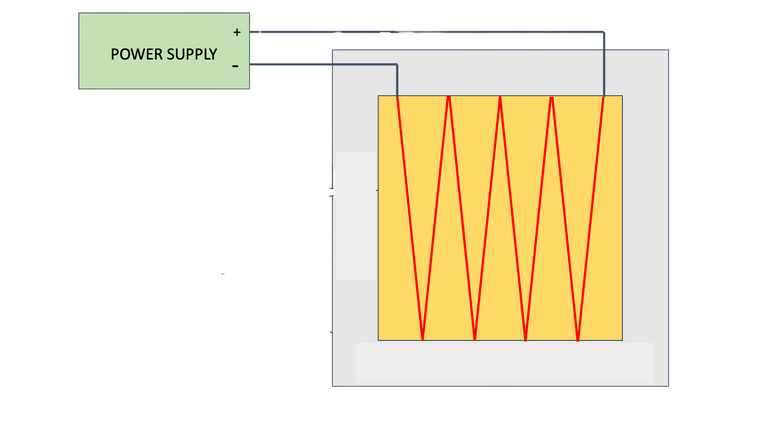

1 KG supply of zeolite molecular sieve sorbent is poured into pocket around wire and sealed with steel plate.

Square sorbent pocket threaded with nichrome wire

sorbent Chamber

Sealed space for air flow and vacuum pressure.

Dampers

Seals sorbent chamber to stop air leakage during adsorption, and enable vacuum pressure.

Fan

Pulls air through sorbent panel.

CO2 Sensors

Fastened to exterior in 3D printed holder at air input and output positions

AIR FLOW activated by fan

How It Works - Current

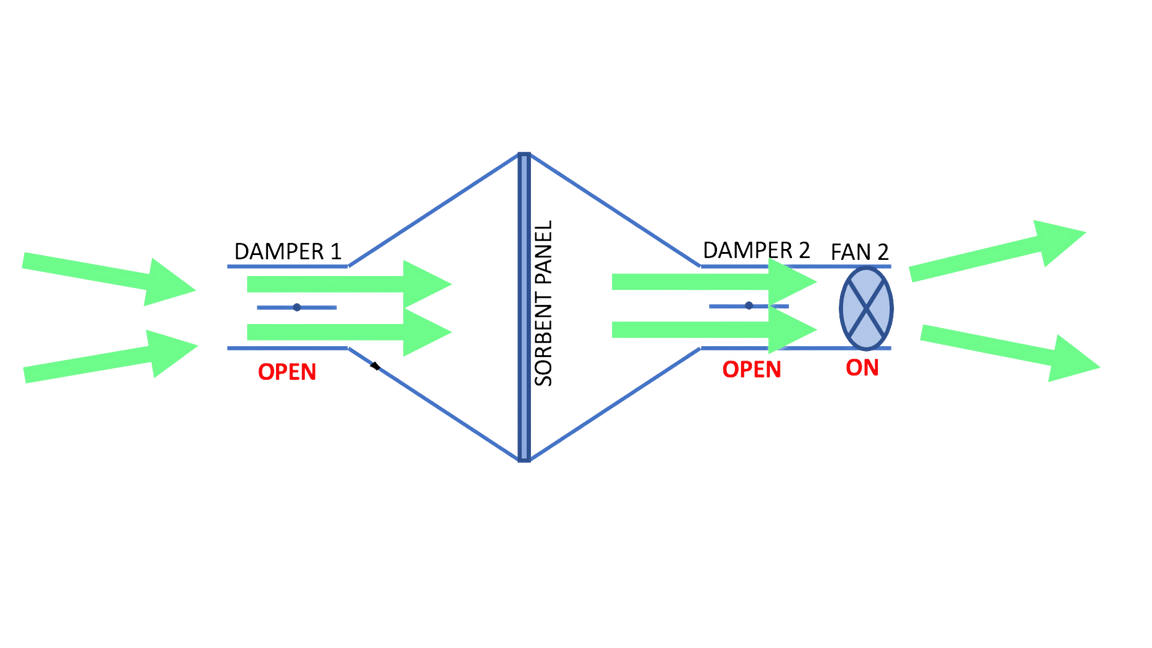

Phase 1: Adsorption

CO2 absorption by sorbent via air contact with fan.

CO2 Sensor 1

CO2 Sensor 2

The fan is activated to pull CO2 laden air through the opposite end of the duct, across sorbent panel, and out the other end. Dampers are open. CO2 concentration of incoming air monitoried with sensor.

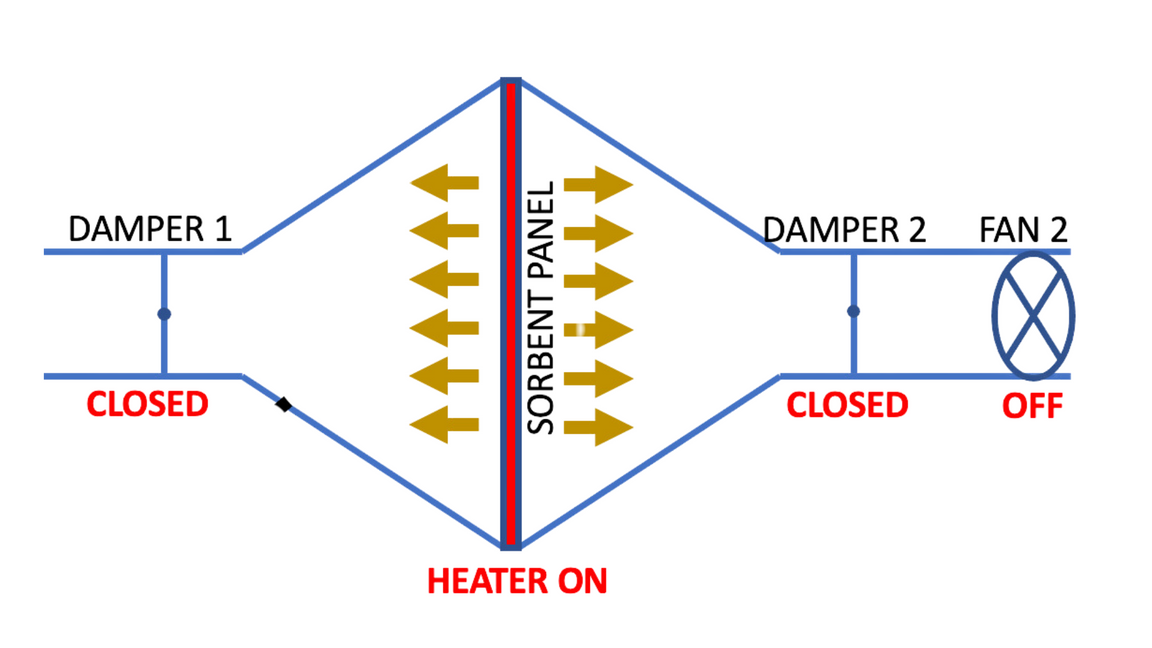

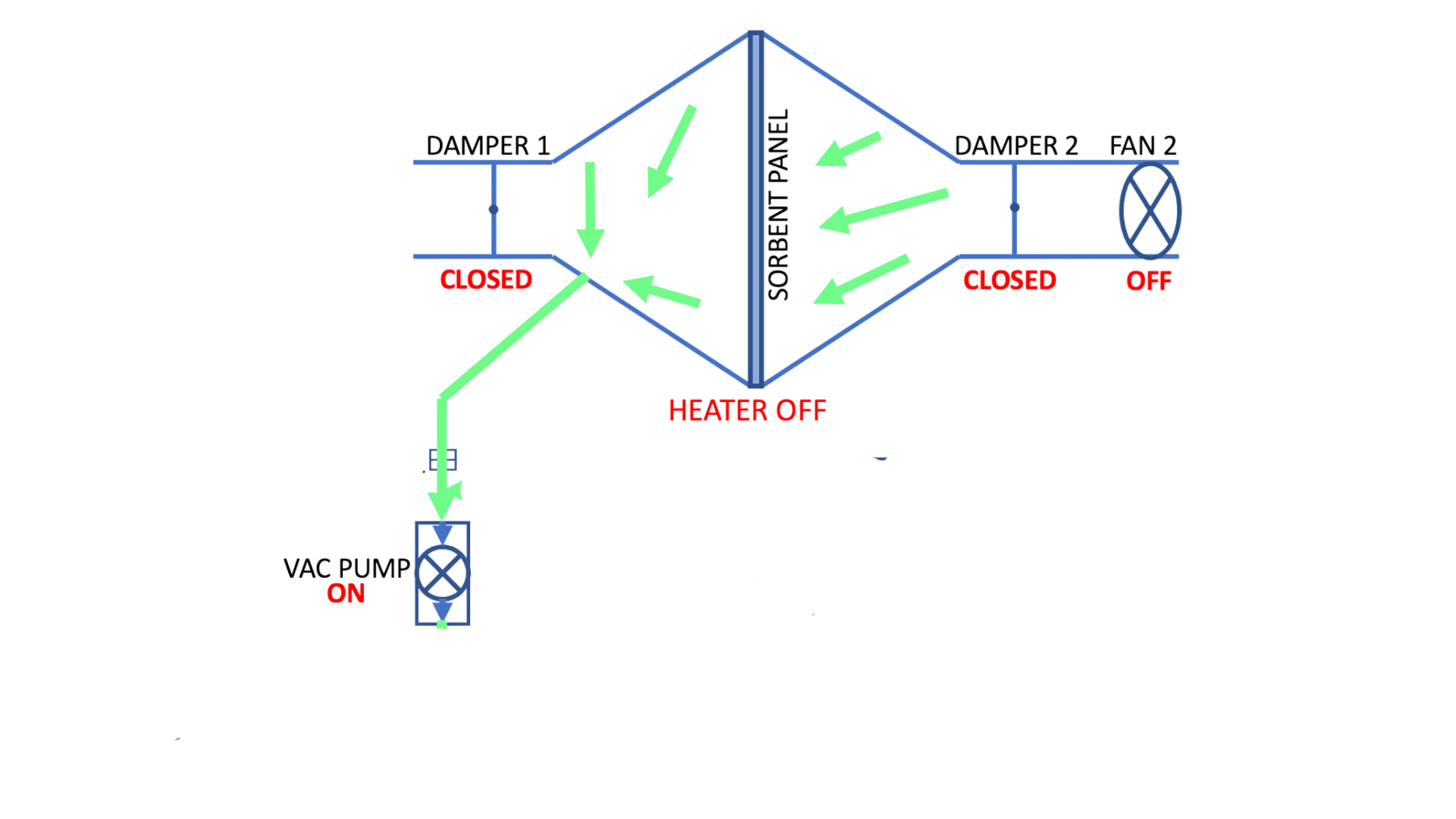

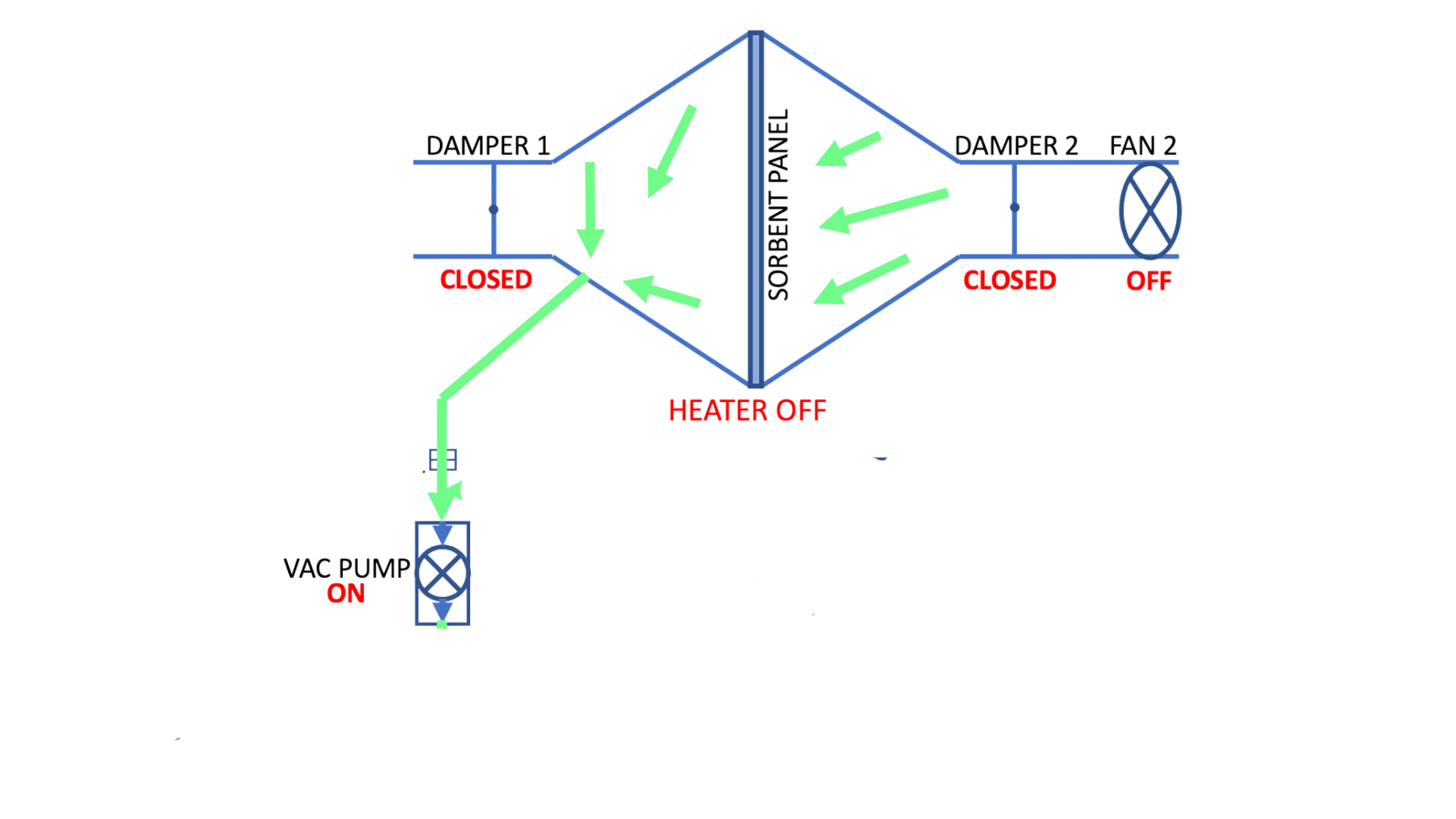

How It Works - Current

Phase 2: Desorption

CO2 released by sorbent using heat and pressure.

CO2 Sensor 1

CO2 Sensor 2

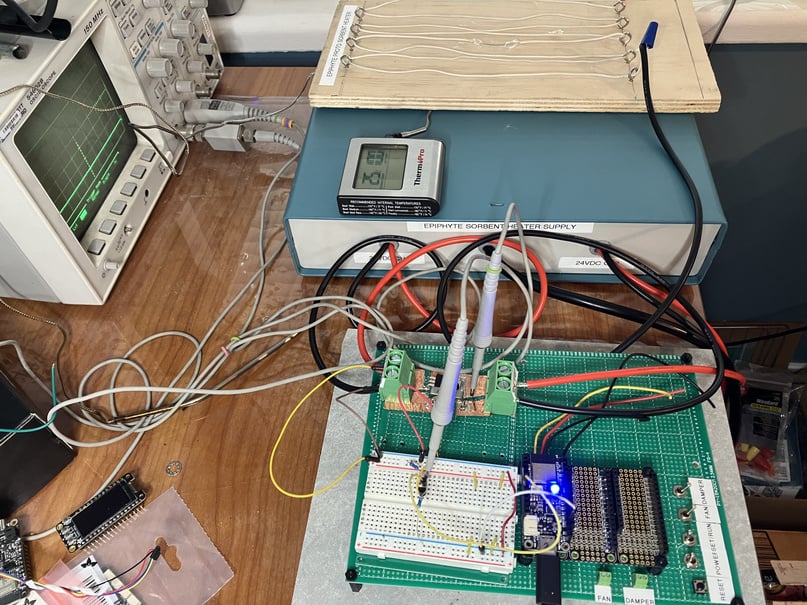

Electro-resistive heating of sorbent with nichrome wire.

Power supply (24V/12A)

The fan is turned off, dampers are closed, and heater is activated to 80 - 100 C to release CO2 from sorbent. Temperature is controlled with programmed microcontroller. Pressure and CO2 in chamber monitored with sensor.

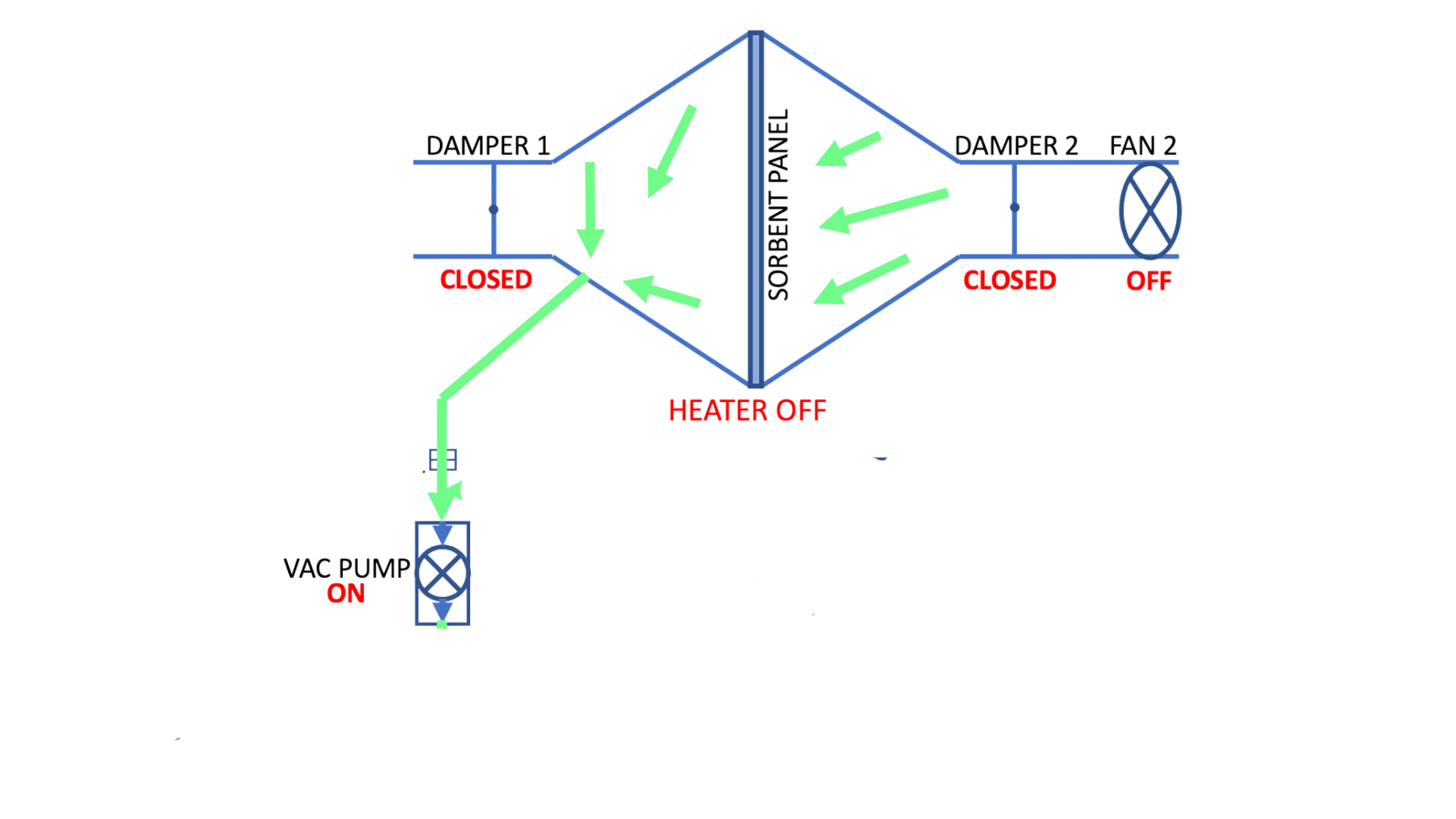

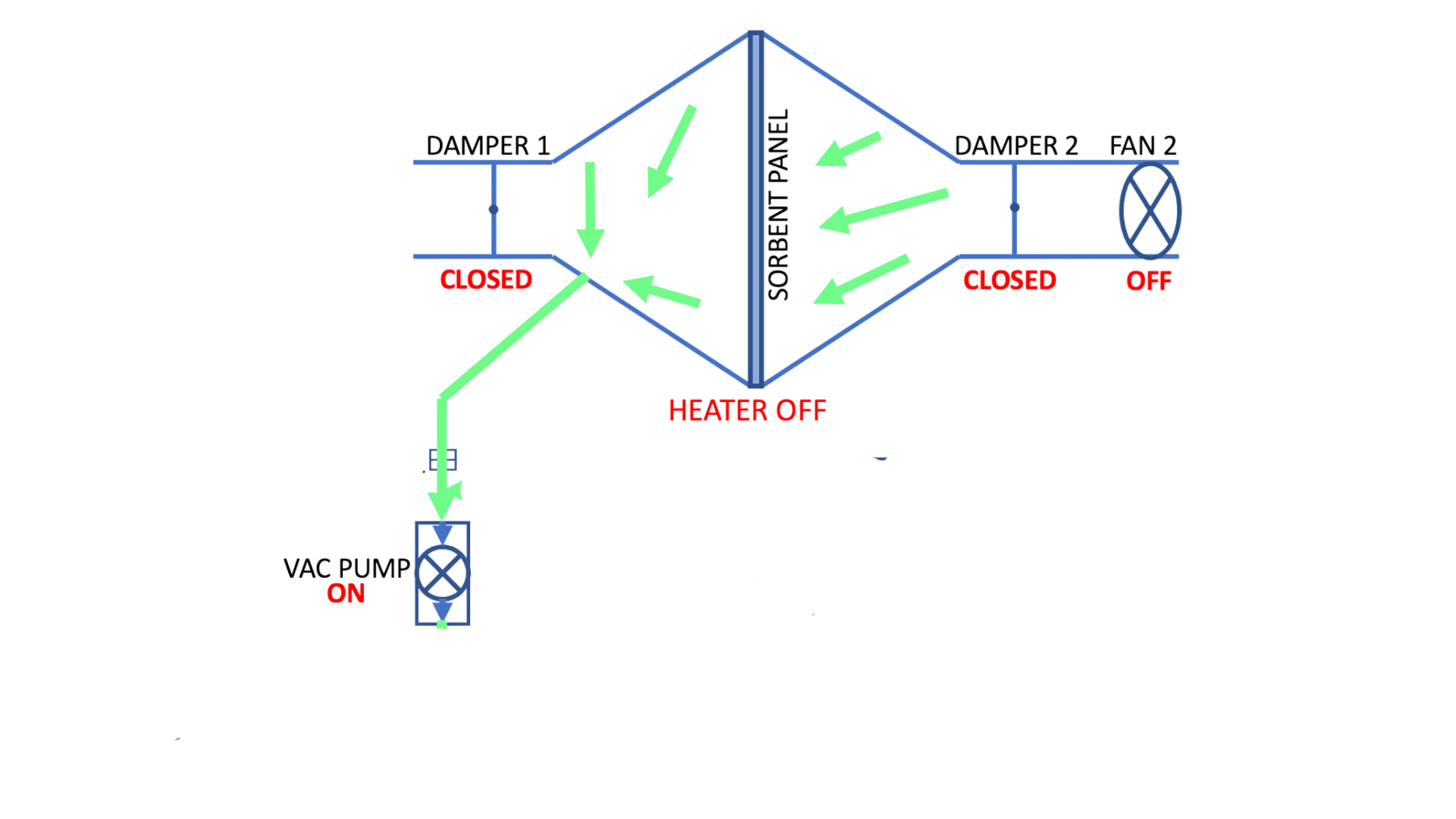

How It Works - Not Yet implemented

Phase 3: Vacuum

CO2 is vacated from chamber with vacuum.

Vacuum pump activated to facilitate separation and removal of CO2 from chamber. CO2 released back into air, or captured in tank.

Immediate Optimization Needs

Spring - Summer 2024

Based on the results of Build #1 construction and testing, the team discovered several optimization challenges that must be resolved before the next build is undertaken this summer. In Spring-Summer 2024, our growing team is working through each optimization need, live steaming its process every Monday. By Summer 2024, the team aims to complete detailed open source documentation on Github so that others can discover, replicate and hack Epiphyte going forward.

Future Development Directions

2024 & Beyond

Completing and publishing the ‘Hello World’ kernel is just the very first step in Epiphyte’s evolution. Our goal is to set the design on a permanent pathway to perpetual innovation, exploration and evolution driven by a diverse, multi-disciplinary community of contributors. Here are a few key development directions that we plan to investigate in the coming months....

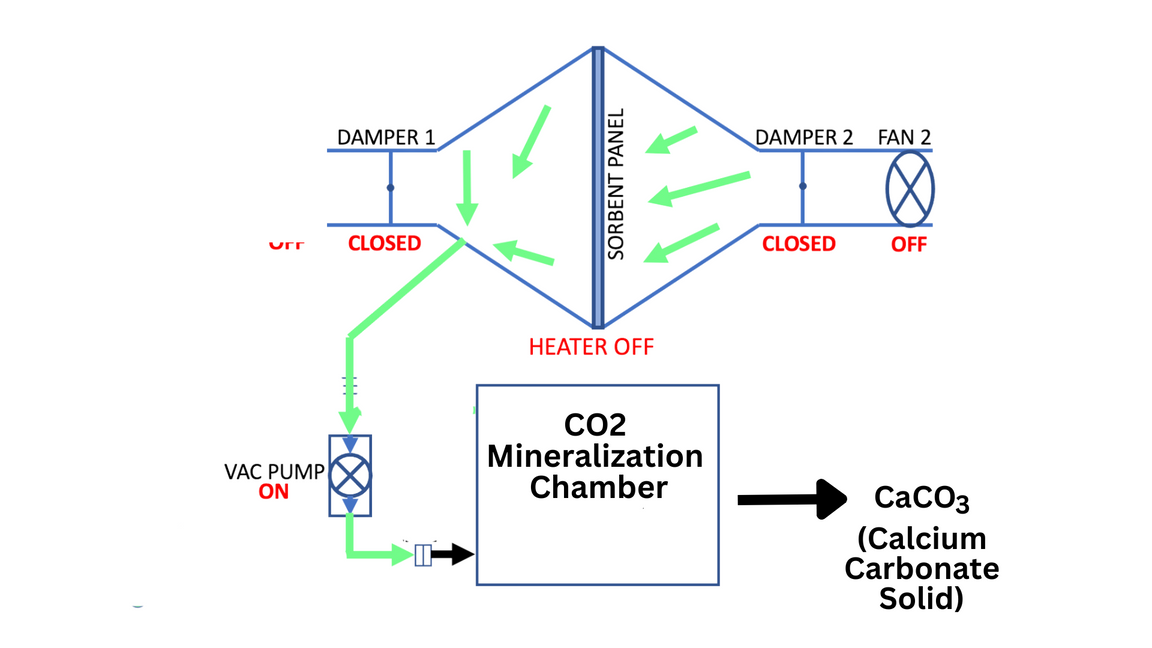

D1. Integrated CO2 mineralization

CO2 pulled from the chamber will be converted to solid CaCO3 using a special catalyst.

CaCO

3

(Calcium Carbonate Solid)

Captured and transferred CO2 enters integrated mineralization chamber, where it is combined with H20, Ca and novel catalyst to produce CaCO3 in solid form, resulting in durable CO2 storage.

D2. Little DACs, Big Data

We want to incorporate IoT monitoring into every Epiphyte built and operating globally. This will allow a range of performance results - both for individual units and in aggregate - to be reported and interpreted in realtime on a single dashboard.

Data Collected

- CO2 Removed

- Energy Efficiency

- Environmental Factors

- Etc.

D3. Printed Carbon Storage

Mineralizing CO2 involves the creation of solid carbonates, such as calcium carbonate (CaCO3). CaCO3 can be blended into 3D printing filament, making it stronger. If Epiphyte integrates mineralization (see D1 above), we can then explore making CaCO3 enhanced filaments. If we are successful with this step, we can then evaluate which Epiphyte components can potentially be 3D printed with this CaCO3 enhanced filament. This would create a pathway to not only removing, but also storing CO2 with/in Epiphytes. It also solves the question “what do we do with the CO2 we capture?” Answer: use it to make more Epiphytes!